Automatic Taping Machine TRM-200

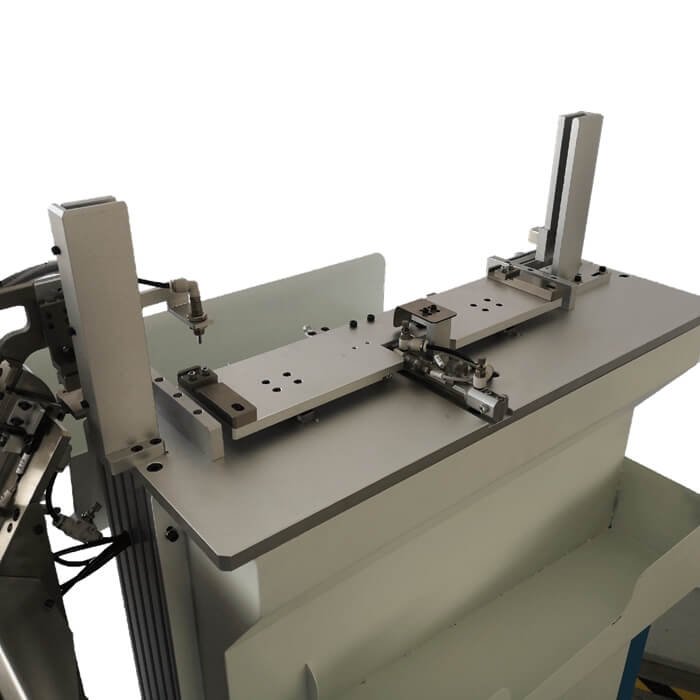

- Adjustable track assembly for tape widths up to 72mm

- Independently controlled seal temperature for each side of the cover tape

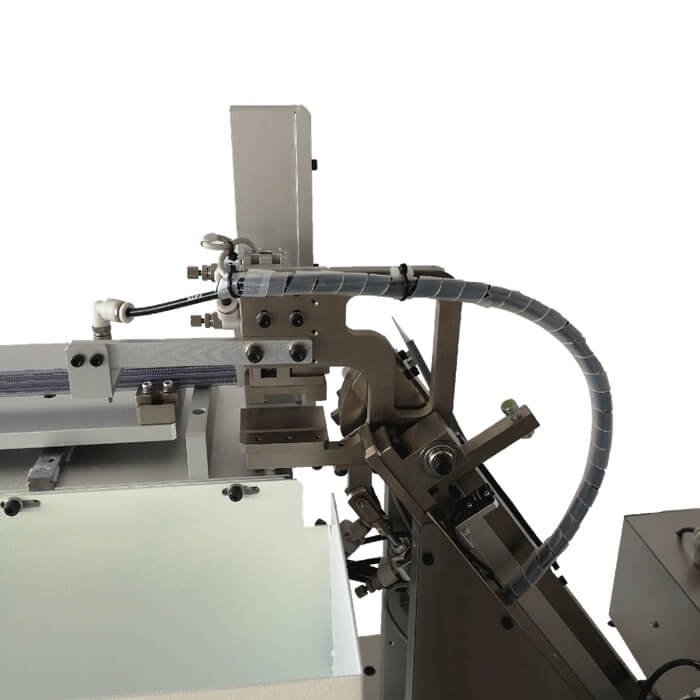

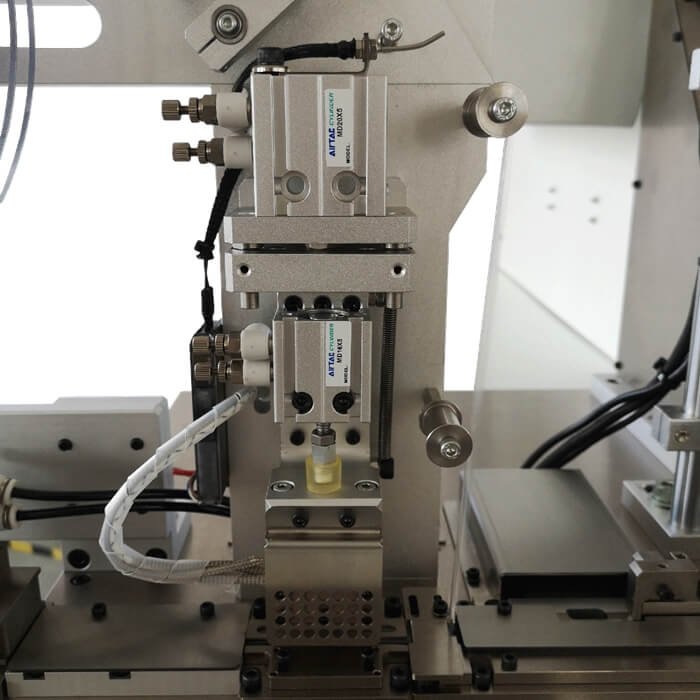

- Dual-stage, fully adjustable heat and PSA sealer assembly

- User-friendly software assures ease of set up and operation

- Software controlled advance movement of carrier tape (2mm – 144mm pitch)

- Dimensions: H 15″ (38cm) x W 55″ (140cm) x D 20.5″ (52cm)

- Power required: 120/230 VAC, 50/60 Hz, Compressed air 80 PSI

- Accommodates 8-72mm wide carrier tape

Detail About Automatic Taping Machine TRM-200

1.Overview

The product is automatically loaded by the tube, sucked by robot, then put into the carrier belt and sealed. IC for SOP8\14\16 package. In addition to the basic taping function, image detection and other functions can be added according to customer process requirements. The device is suitable for a wide range of carrier tapes, which can be sealed with a width of 12, 16 mm.

2. Features

- The track width can be flexibly adjusted in the range of 12-56 mm.

- The position of the sealing knife can be fine-tuned to <0.1mm.

- Independent PID temperature control of double sealing cutter, accurate and stable temperature control;

- The tension of the cover belt can be adjusted and the position of the cover belt can be fine-tuned.

- Stepless adjustment of belt pulling speed;

- Enumeration adopts industrial encoder, which is simple and reliable and ensures accurate counting.

- The loading and unloading discs are simple and compatible with all EIA-481 standard discs.

- Manual and pedal switches can control the start and stop of the machine to facilitate the operation of the equipment.

- The machine is controlled by PLC, which is stable and reliable.

3. Specifications

4. User Manual

https://tapereelmachine.com/downloads/user-manual/TMR-200_Vision_Checking_Instructions.pdf

5. Video

Share Automatic Taping Machine TRM-200 With Your Clients

Share to LinkedIn

Share to Facebook

Share to Twitter